Microparticles safeguard vitamins and information

Imagine creating part of a meal for the visionary Bill Gates himself. But as a scientist, not a chef.

Ana Jaklenec, did exactly that when she was a research scientist working with Robert Langer, a David H. Koch Institute for Integrative Cancer Research professor at the Massachusetts Institute of Technology.

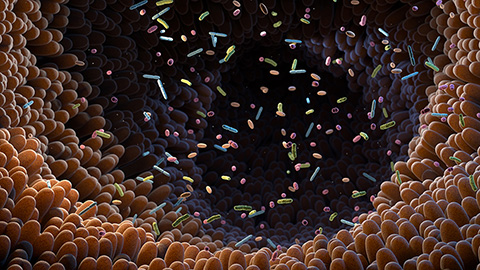

Jaklenec and Langer teamed up with the Bill & Melinda Gates Foundation to work on a strategy to fight malnutrition, which affects more than 735 million people worldwide. They developed a microparticle that can encapsulate micronutrients, or vitamins and minerals, which can be incorporated into staple foods such as flour, thus preventing nutrient decay during storage.

Food and drug storage strategies have long supported health and nutrition, but primarily in the background, especially in affluent nations. However, the COVID-19 pandemic brought the importance of drug storage and delivery into the spotlight, as the COVID-19 vaccine required subfreezing conditions to remain stable. Freezer shortages plagued the U.S., and rural and low-income hospitals could not afford these appliances.

In developing nations, storage requirements can prevent people from receiving basic medical care. One study showed that only 38% of generic medicines are publicly available in low- and middle-income countries due to poor stock management. The same principles apply to food storage, causing malnutrition to run rampant in developing nations.

To combat these storage and availability issues, Jaklenec, now a principal investigator at the David H. Koch Institute for Integrative Cancer Research at MIT, created ready-to-use systems that preserve nutrients and enhance data storage.

“Our work has shown that we can store a lot of valuable things in different ways,” Jaklenec said.

Nutrient boost

According to a study by UNICEF scientists, flour loses more than 45% of its vitamin A content within three months when kept around 77 °F. However, in high-heat conditions, similar to those in developing African nations, more than 85% of flour’s vitamin A disappeared within three months.

Micronutrients are inherently unstable and have short shelf lives, making it difficult to incorporate them into food staples.

“We know that for many (nutrients), absorption is better via food rather than pills or supplements,” Jaklenec said. “So that was the motivation behind this project.”

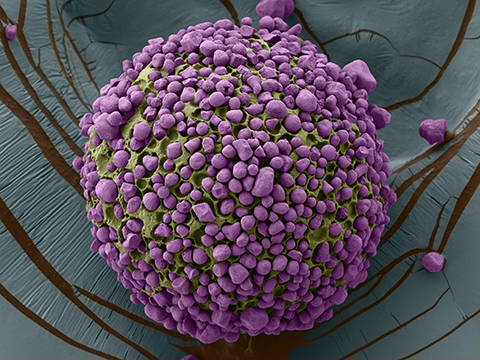

Jaklenec and her team created a heat- and water-stable microparticle slightly larger than the diameter of a human hair made up of an oil-soluble copolymer of dimethylaminoethyl methacrylate, butyl methacrylate and methyl methacrylate, also known as basic methacrylate copolymer or BMC. The team added iron-containing BMC to flour and fed volunteers, including Gates, bread baked with the fortified flour. The recipients absorbed iron encapsulated in BMCs at similar percentages to free iron.

Both Langer and Gates tried the bread made with fortified flour. “And we're all doing fine," Langer said in a press release.

In the lab, Jaklenec and Linzixuan “Rhoda” Zhang, a graduate student at MIT, have taken BMC a step further and loaded it with vitamin A. In some regions of sub-Saharan Africa and South Asia, more than 45% of children are vitamin A deficient, which can cause blindness.

Compared to free and commercially available encapsulated vitamin A, vitamin A–BMC microparticles remained stable two and six hours longer, respectively, in boiling water. When they incorporated vitamin A–BMC microparticles into bouillon cubes, the microparticle became even more stable.

The team next used rats to examine how well-cooked vitamin A was absorbed, either free or encapsulated in BMC. Vitamin A absorption was nine times greater in rats fed vitamin–A BMC microparticles versus free vitamin A.

One of the biggest difficulties of working in food science, Jaklenec and Zhang said, is the scale-up needed to use a product in humans.

In the lab, the team used an oil-water emulsion fabrication process to create the vitamin A–containing microparticles. However, they had to adapt and scale up their methods to create enough microparticles for a clinical trial.

“When I started applying our work to the field of nutrition, I was very surprised to find that the volumes are enormous compared to those in drug production,” Jaklenec said. “With a blockbuster pharmaceutical drug, the production volumes are much less per year compared to food. They are on the order of thousands of metric tons, not kilograms. So, it’s important to address the challenges associated with scaling-up production.”

When tested in humans, their vitamin A–BMCs were absorbed in the stomach and gut similarly to free vitamin A.

Jaklenec and her team are now working on a different encapsulating microparticle. BMC works well at protecting micronutrients. However, it is only soluble once it reaches the acidic stomach and is a nonbiodegradable polymer. Jaklenec said this generates some concern that BMC polymers might be a harmful environmental by-product of food fortification.

Therefore, Zhang created a novel microparticle that is broken down to sugar and amino acid-based derivatives by hydrolysis during the cooking process.

The lab has done preliminary testing of this microparticle, and Zhang is working with external stakeholders to get U.S. Food and Drug Administration approval by scaling up production and obtaining a Chemical Abstracts Service, or CAS, Registry number. The CAS Registry contains authoritative information on more than 204 million unique organic and inorganic substances and 69 million protein and DNA sequences.

“We hope this polymer will be on the shelf one day,” Zhang said.

Information age

The word storage brings food and other tangible items to mind. But one of the world’s biggest storage challenges has nothing to do with consumables: information storage and, in particular, medical recordkeeping. Hospitals in the U.S. produce about 50 petabytes, that’s 1,000 terabytes, of data per year. In fact, about 30% of the world’s data is held by the health care industry.

These data loads require gigantic servers and cloud-based systems. However, in places such as Africa, only 7% of households own a computer, compared with 92% in the U.S. Experts say Africa is trapped in “health data poverty.” Often, people living in poorer African countries do not receive the correct vaccines and boosters to support immunity, in part due to poor recordkeeping, Jaklenec said.

“In certain African countries, they track who has been vaccinated in different ways,” Jaklenec said. “Some are very crude, such as using a Sharpie to mark a fingernail, while others are very sophisticated such us using fingerprints and storing them in a database.”

Using something like fingerprints and markings to keep track of vaccinations, is not only impractical, but also an invasion of privacy, Jaklenec said.

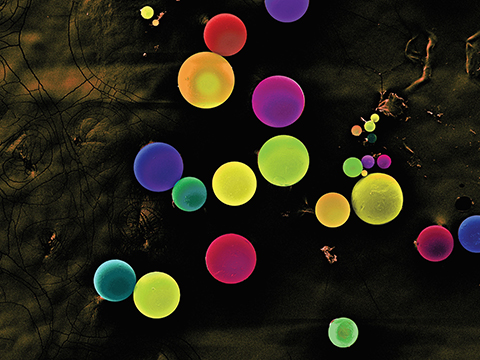

To combat these public health issues in conditions of poor technological infrastructure, Jaklenec came up with the idea to record vaccinations and other medical information on a person’s skin in a sort of invisible tattoo. The team took a unique approach using quantum dots. These ultrasmall semiconductor nanoparticles exhibit size-dependent color and florescence properties — and clinched the Nobel Prize in chemistry in 2023.

Jaklenec said 100 dots fit on the tip of a finger.

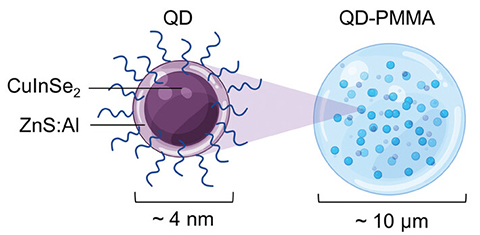

Quantum dots comprise a core–shell structure, much like an atom or lipid nanoparticle. Jooli Han, a postdoctoral fellow in the Jaklenec lab, synthesized these particles, which contain a copper, indium and sulfur core surrounded by a zinc-sulfur shell.

“You can easily change the core size to emit different wavelengths of light and create a rainbow of colors,” Han said.

Once Han created the shell and core, she encapsulated the dots in an FDA-approved, nonbiodegradable polymer, poly(methyl methacrylate), or PMMA. Quantum dots are only visible in the near-infrared in response to the correct wavelength of light, in this case, an infrared laser or flashlight.

To deliver the quantum dots to the skin, Jaklenec and Han loaded them in sugar-based microneedle arrays.

“Microneedles are used in the cosmetics industry to firm up the skin by perforating the skin and inducing wound healing,” Jaklenec said. “Those are made of metal, but ours dissolve and leave behind whatever was placed in the tips.”

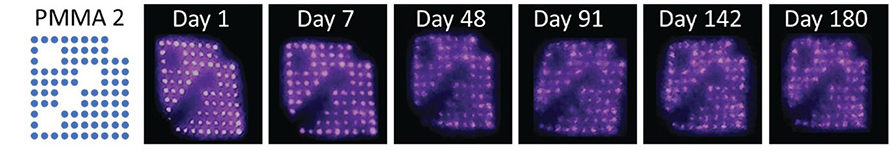

The microneedles allowed them to arrange the quantum dots into a grid-like pattern, which could store information. The team refers to their tech as “on-patient medical records.”

After injecting the nanoparticles into the dermis layer of the skin of rats, the signal was visible for more than 180 days under an infrared light. The team also completed solar simulations, often used for sunscreen testing, to examine the effect of sunlight on the quantum dots’ durability. Under these conditions, the test indicated the dots would last for about five years in the skin.

Even though the polymer used to encapsulate the quantum dots is nonbiodegradable, the immune system will eventually clear the foreign particles, Jaklenec said.

However, the researchers can vary the encapsulating polymer to make the quantum dot signal more or less durable. They found that a different polymer, poly(lactic-co-glycolic acid), or PLGA, is biodegradable, which makes it disappear from the skin faster.

With these advances, Jaklenec plans to create more complex, QR code–like patterns to store billions of bits of information in one place.

She added that she would like to make a form of this technology available for the public someday if there’s consumer interest.

“There may be a use for this (technology) outside of medicine,” Jaklenec said. “There might be a market in body art. People could get an invisible marking with secret messages for loved ones … It could also be useful for concert or event attendance.”

Enjoy reading ASBMB Today?

Become a member to receive the print edition four times a year and the digital edition monthly.

Learn moreGet the latest from ASBMB Today

Enter your email address, and we’ll send you a weekly email with recent articles, interviews and more.

Latest in Science

Science highlights or most popular articles

Ragweed compound thwarts aggressive bladder and breast cancers

Scientists from the University of Michigan reveal the mechanism of action of ambrosin, a compound from ragweed, selectively attacks advanced bladder and breast cancer cells in cell-based models, highlighting its potential to treat advanced tumors.

Lipid-lowering therapies could help treat IBD

Genetic evidence shows that drugs that reduce cholesterol or triglyceride levels can either raise or lower inflammatory bowel disease risk by altering gut microbes and immune signaling.

Key regulator of cholesterol protects against Alzheimer’s disease

A new study identifies oxysterol-binding protein-related protein 6 as a central controller of brain cholesterol balance, with protective effects against Alzheimer’s-related neurodegeneration.

From humble beginnings to unlocking lysosomal secrets

Monther Abu–Remaileh will receive the ASBMB’s 2026 Walter A. Shaw Young Investigator Award in Lipid Research at the ASBMB Annual Meeting, March 7-10 in Washington, D.C.

Chemistry meets biology to thwart parasites

Margaret Phillips will receive the Alice and C. C. Wang Award in Molecular Parasitology at the ASBMB Annual Meeting, March 7-10 in Washington, D.C.

ASBMB announces 2026 JBC/Tabor awardees

The seven awardees are first authors of outstanding papers published in 2025 in the Journal of Biological Chemistry.